By: Joe Battle on September 3rd, 2024

Thinking Out(side) The Box: Stick to the plan

Welcome back! I just finished reminiscing about my time working in the maintenance department of a medical device manufacturer. I was considered to be on the “Front Line,” where we were the first line of defense for arising fires/issues with assets. Our duty was to get the machines back up and running and decrease downtime. As I briefly discussed in part 1, Graphical Scheduler and its applications can assist in the preventative initiatives to decrease downtime. Walk down memory lane as I talk about the ways we could have solutioned some of those fires we had to fight. We will use Alex the Planner and Sam the Supervisor to conquer the challenges of maintenance management with IBM Maximo's Graphical Scheduler and Graphical Work Week. These two applications work together to bring order, efficiency, and a bit of fun to their daily tasks.

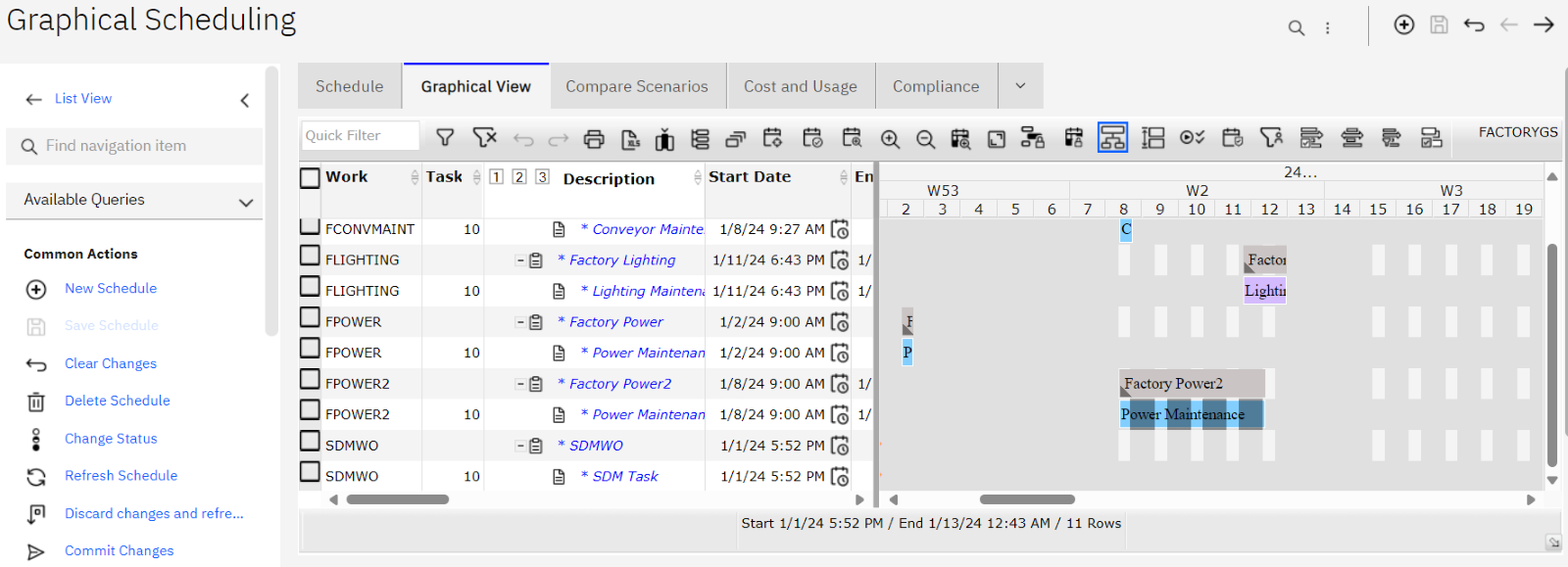

Alex the Planner began the day with a strong cup of coffee, logging into IBM Maximo's Graphical Scheduler to review the incoming maintenance requests. With the new tasks prioritized and resources allocated, Alex used the drag-and-drop functionality to craft a balanced and conflict-free schedule. By 8:30 AM, the schedule was ready, and Alex felt a sense of accomplishment.

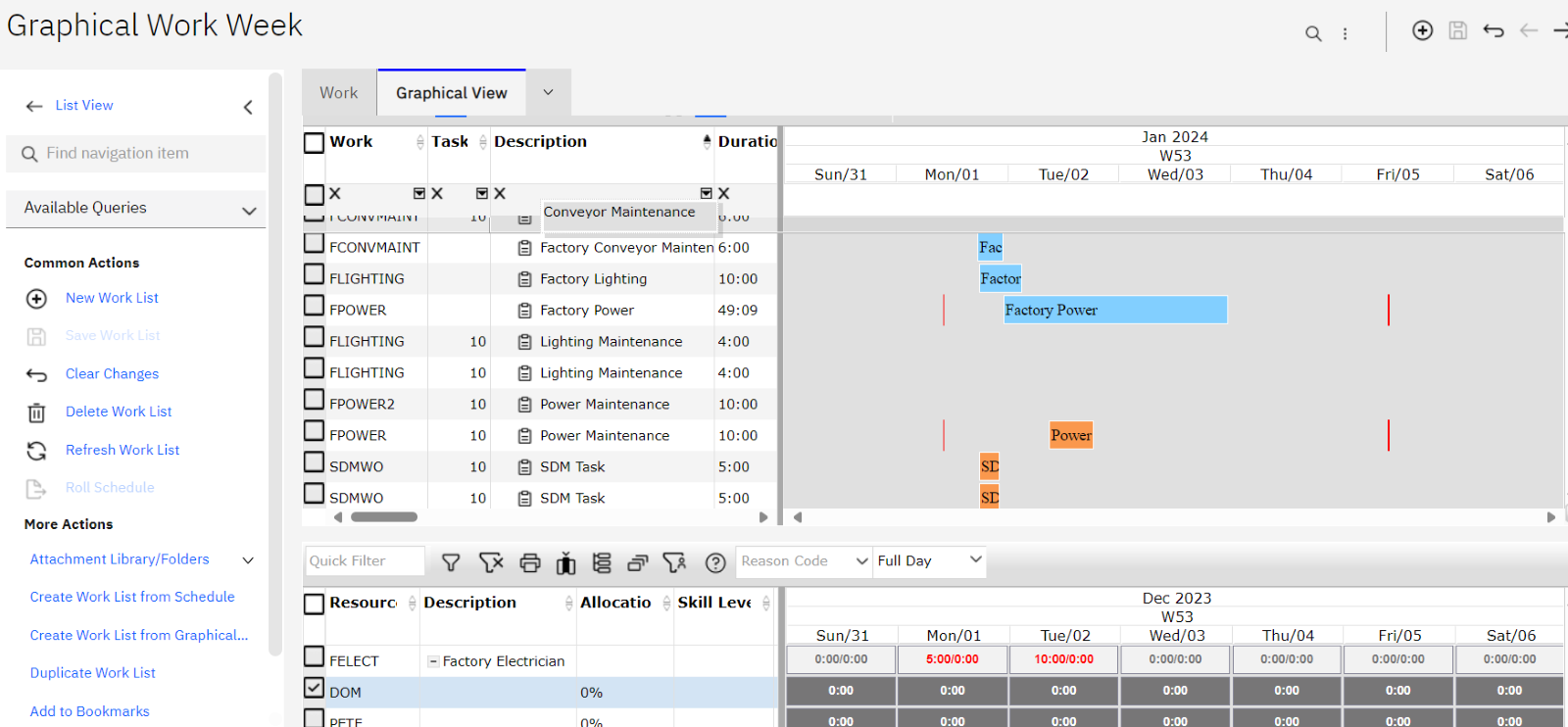

At 10:00 AM, Sam the Supervisor gathered the team for the morning huddle, displaying the day’s schedule via the Graphical Work Week. As the team reviewed their assignments, a technician highlighted a potential issue with a scheduled task. Sam noted the feedback and planned to discuss it with Alex.

Shortly after, Alex and Sam met to make real-time adjustments based on the technician's feedback. Alex easily moved tasks around using the Graphical Scheduler, demonstrating the seamless integration of the tool. By noon, both Alex and Sam took a well-deserved lunch break, laughing about the pre-Maximo Scheduling days of sticky notes and paper trails.

In the afternoon, Sam conducted a mid-day check-in using the Graphical Work Week to monitor progress. Spotting a delay, Sam reassigned tasks to maintain workflow efficiency. Meanwhile, Alex handled an urgent conveyor belt repair request, promptly adjusting the schedule and informing Sam, who quickly briefed the team.

As the day wound down, Alex and Sam reviewed the day’s accomplishments and prepared for tomorrow. They evaluated completed tasks, noted any delays, and started drafting the next day's schedule. By 5:00 PM, they wrapped up their day, briefed the team, and celebrated another successful day with a high-five, made possible by Maximo’s powerful tools.

As Alex headed home, there was a sense of accomplishment, knowing that tomorrow's challenges would be met with the same efficiency. Sam left the office confident in the tools at their disposal for another day of smooth operations. And so, another day ended in the maintenance world, where technology and teamwork turned potential chaos into a well-oiled machine.