Radio Management for Municipalities & Building Complexes Using Maximo Ver. 7.6.1.3

(Receive, Request, Issue, Inventory, Return for Repairs, Accountability, and Reporting)

This article will discuss and describe how to use Maximo to Manage your municipalities or large building complex radios. Most organizations will have a 5-to-10-year contract with a radio manufacturer and work with them on programing and securing radio usage. Organizations will use different frequencies and radio codes by department and that will all be set up by the radio manufactures and distributers. This article will detail how to manage and account for your organization’s radios, it will not include dispatching, service calls, or programing radios; only discussing management and accounting for the actual radio assets in Maximo.

A customer switching their radio contract, and the biggest issue was accounting for lost or misplaced radios from the previous contract. Additionally, managing their radios using excel and other manual processes was not working.

The goal is to use Maximo to manage their new contract for radio’s to give them the ability to record history and hold users accountable for condition and custody. They also want the ability to Store, Request, Issue, Return for Repairs, Inventory, Account, and Report on the status of their Radio’s from their Maximo Application.

This Article in general terms will discuss how is goal can be accomplished in Maximo.

Typical Radio Project Plan for organizations:

1. Budget and purchase radio’s (Example: Motorola APX6000).2. Receive radios in Maximo.

3. List, identify, issue radios to departments and users.

4. Program radios.

5. Distribute radios.

6. Maintain storeroom bins for spare radios spare radios.

7. Place radio assets into Maximo Assets application.

8. Create radio request form in Maximo. (Maximo Cloned App).

9. Configure Maximo to manage radios for receiving, issuing, returning, Inventory, and redistribution after repairs).

10. Create radio accountability program with and reporting on status of radios, (Maximo 11. Start Centers and BIRT Reports)

Your organization will need to write up detailed requirements to meet your business processes, policies, and business rules.

The customer did that using the following Maximo configurations to meet their requirements and this article will present considerations in using Maximo for your organizations radio management process. This article explains how each Maximo Application was used and how to piece the end-to-end process together for a global approach to radio management.

Roles of people that Manage Radios:

- Radio’s Project Sponsor

- Inventory Manager

- Department Supervisors

- End Users

- PMO (for Accountability of Radio’s)

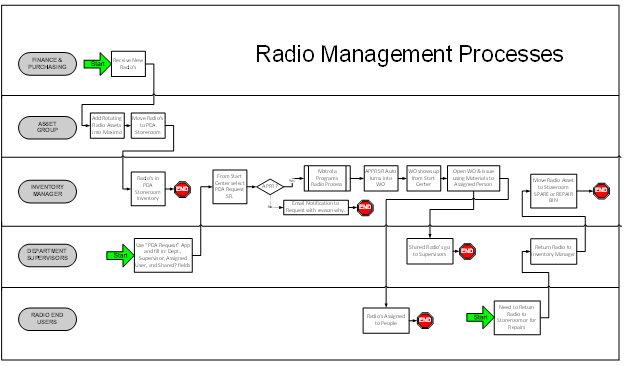

Process Diagram for End-to-End Radio Life Cycle:

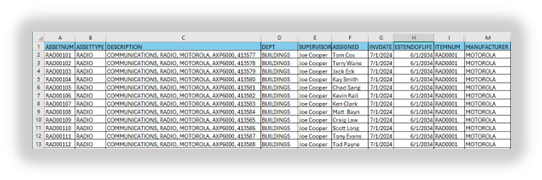

Original List of Radios:

Use Excel to create a file with all the Radio’s Asset Numbers, Descriptions, Classifications, Department, Department Leads, Assigned to Users, Manufacture, Models, S/N, and any other vital information. This file will be used to distribute Radio’s.

Small Sample for Excel File:

On distribution day users will turn in old radio and receive their new radios with correct programing and barcode.

This original list of Radio’s file will also be used as the Maximo Load Script for the Assets Application using the Application Import function to get radios into the Maximo Assets Application. Other methods can also be used to import the list of Radios into Maximo. We used the OOB Application Import function from the Asset Application.

Maximo Applications Used:

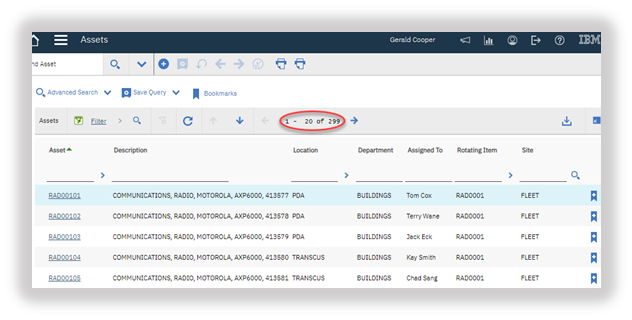

Assets ApplicationOur customer started with approximately 400 Radio’s. The Assets Application is where the primary information for the Radios is stored. The ASSETNUM has a prefix of “RAD” to help filter the radio assets. The description uses an Assets Radio Classification to name the new assets. Radios also get entered as Rotating Items which we will discuss later and is used to Move and Issue radios to keep history information. Manufacture, Model, S/N, Inventory Date, and Purchase Price are all important fields and part of the Radio Asset.

Here is the list view in Maximo for the Radio Assets:

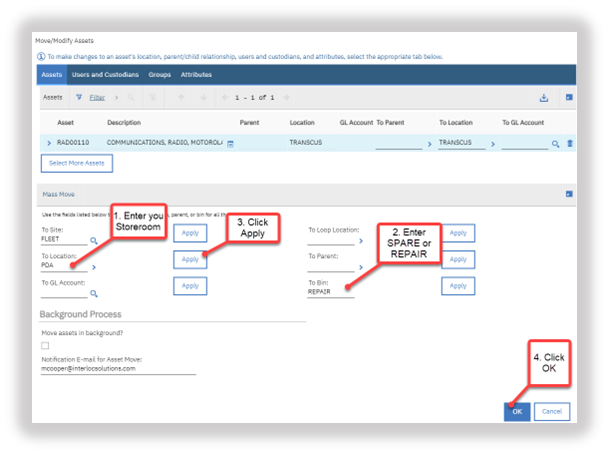

Move/ Modify Assets

From the Assets Application Maximo Users will select the Common Actions option to “Move/Modify Assets” to move a radio asset to the Storeroom SPARE or REPAIR BIN. User to select the radio asset from the list view that they want to move then select the Move/Modify Assets Option, the follow the process below. The radio will now be identified to the Storeroom and the radio will be available for distribution or available to send out for repairs.

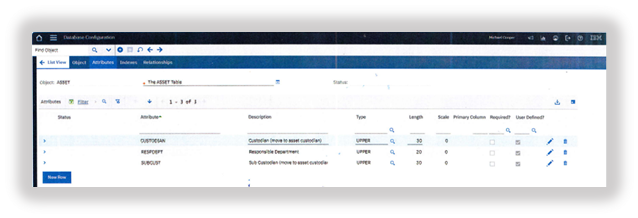

- Database Configuration

For this Radio Project four primary fields where used:

- Department:

- Lead Supervisor:

- Assigned To:

- Shared:

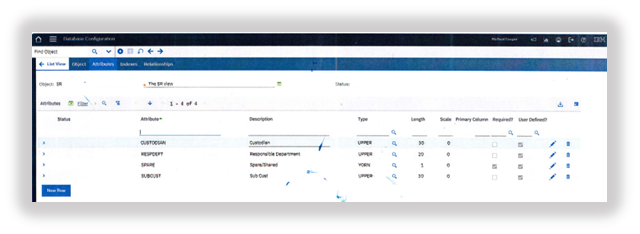

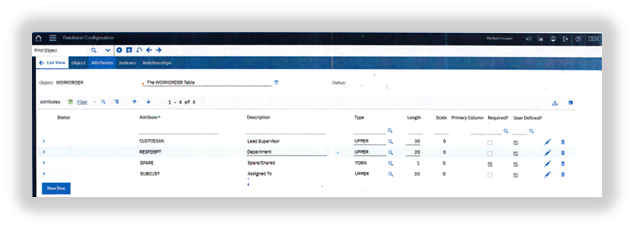

These four fields were added to the ASSET, SR, and WORKORDER Objects.

ASSET:

SR:

WORKORDER:

For these fields Relationships and Crossover Domains was setup to pass information between applications.

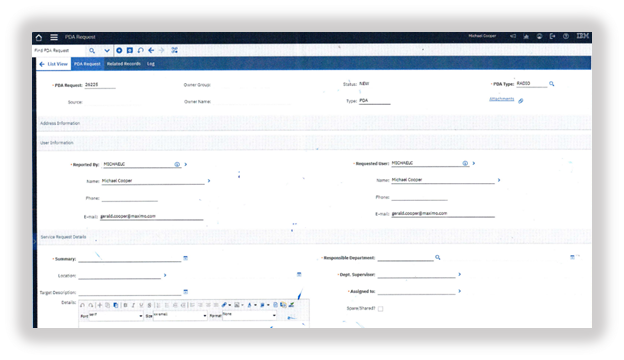

- Cloned SR Application to create “PDA Request Form”

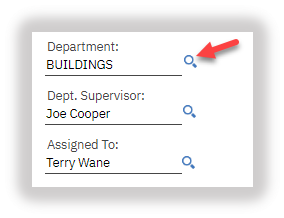

The SR Application was used to create a “PDA Request Form” Application where Maximo Users make their request for a new radio. The Request Application is a major part of the radio process. The requester fills out the form with PDA Type, Department, Lead Supervisor, Assigned To, or Shared with some other pertinent information, then saves the record.

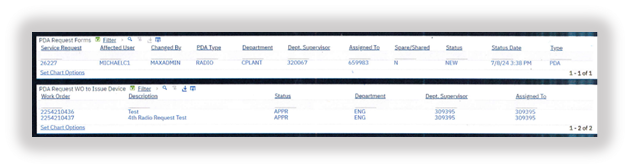

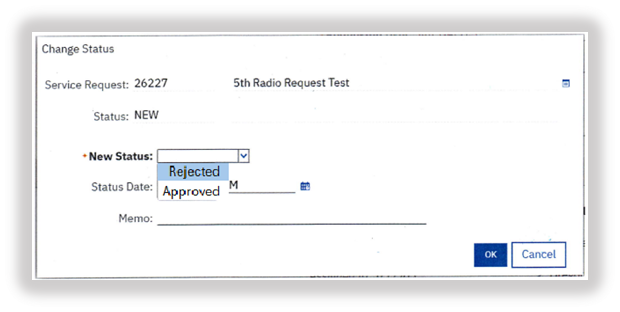

The created and saved SR Record then shows up in the Inventory Manger Start Center where they will open the request and approve or reject the request by changing the SR Status to APPR or REJECT.

The Cloned Application is configured when the request is approved to Create a WO with all the SR information using a crossover domain. And if the Request is Rejected then an e-mail notification is sent to the requester with the reason for the rejection. If the Request is Approved then an e-mail notification is sent to the requester that the Radio Request has been approved and is being processed. On Approval Maximo is configured to create a WO to be used to issue the radio to the assigned person. The created WO can be viewed and accessed from the cloned Application - Related Records tab.

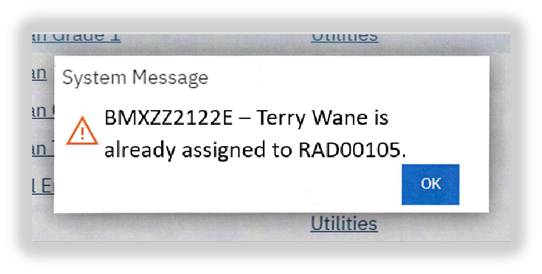

Another configuration made is the PDA Request Form will not allow a person to have two radios assigned at once. If the “Assigned To” person already has a radio, then a System Message pop-up appears: “This Person Already has a Radio Assignment” and Maximo will not allow the person to be assigned, or the record saved.

- Person Groups & Domains

Person Groups are used to filter the respective department people. Assets, SR Cloned Application “PDA Request Form” and Work Order Tracking all have these three attributes: Department, Department Supervisor, and Assigned To fields. The Department field uses a “DEPARTMENT” Domain and once the Department is selected then the Dept. Supervisor and Assigned will get filtered using the Department Person Groups. The listed Person Groups hold approximately 400 people. These Person Groups are managed by the Maximo Administrator in the IT Department.

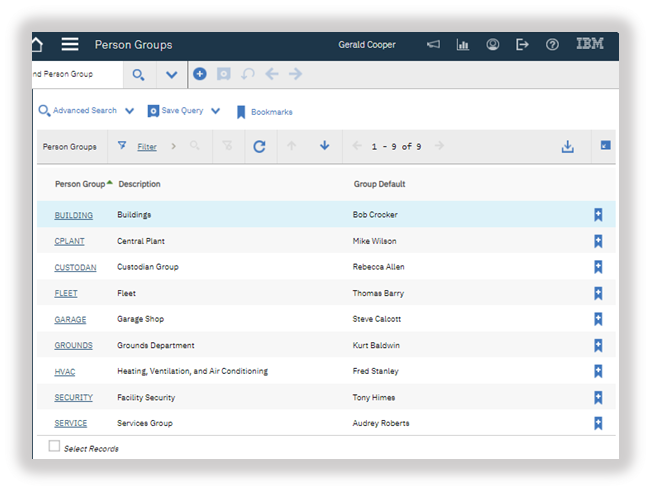

Person Groups:

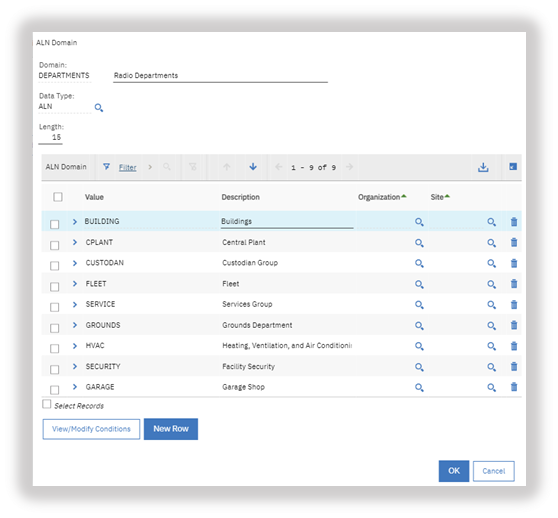

Department Domain:

- Communication Templates

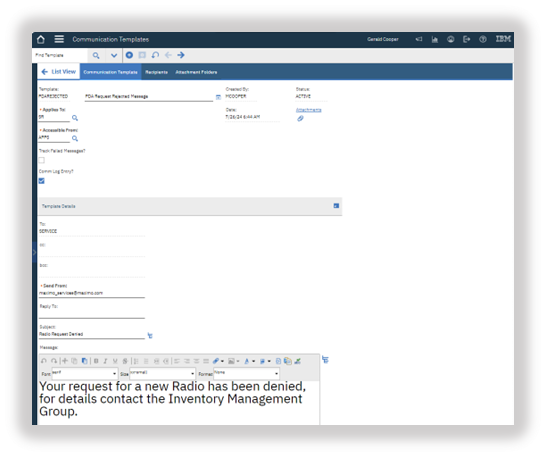

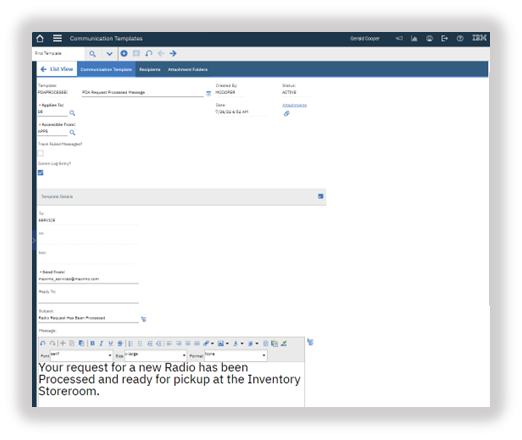

Communication Templates is used for two scenarios: When the request gets rejected and when the request is processed and radio ready for pickup.

When the PDA Request Form is rejected, below is the message that gets sent to the Radio Requester.

When the PDA Request Form is approved and processed by the Inventory Manager, the Requester is sent this message that the radio is ready to be picked up at the Inventory Storeroom.

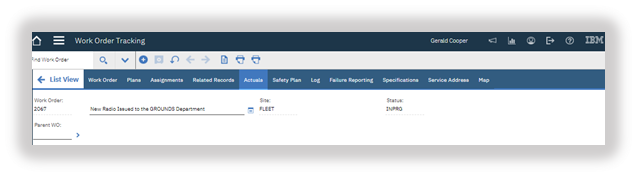

- Work Order Tracking

The Work Order Tracking Application is used to issue the Radio from the SR Object Request record using the Actuals and Materials tab. All the requester information is passed from the Request to the Work Order including the Department, Lead Supervisor, and Assigned To or Shared.

When the Inventory Manager process the Work Order the Rotating Radio Asset gets moved to the “Assigned To” person Location and when the Work Order is completed the WO’s Department, Lead Supervisor, and “Assigned to” values get copied to the Radio Asset Record. The Inventory Manager opens the created Work Order:

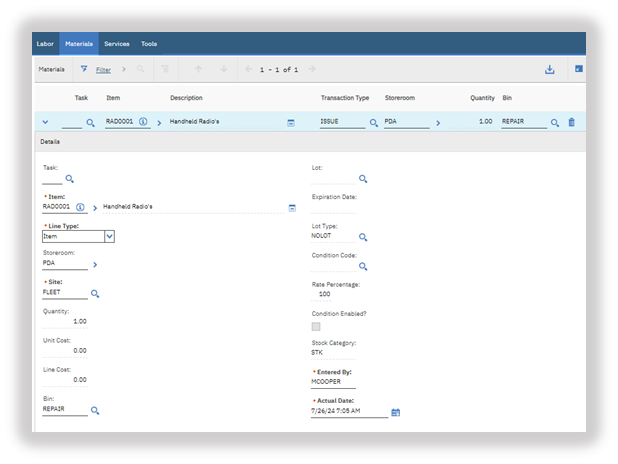

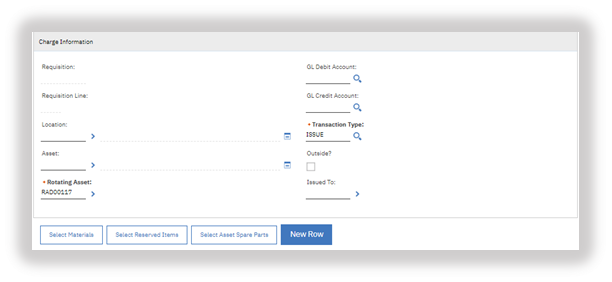

Then they go to the Actuals Tab and select the Materials Tab. And fills in the Rotating Items and Storeroom.

Then they select the Radio to be Issues from the Storeroom.

And after the Radio information is entered into Maximo they will distribute the Radio to the Department Supervisor or Assigned Person.

From the Start Center and list of Assets the assigned Radio will have a Location Type of OPERATING. Radios that are in the Inventory Storeroom Bin location, they have a Location Type of STOREROOM. A quick look by the Dept. Supervisors, the Location Type field is used to know if the Radio has been distributed or available to be issued.

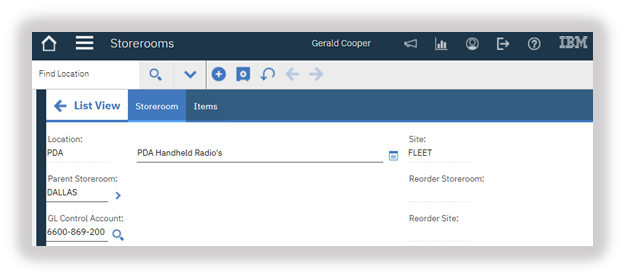

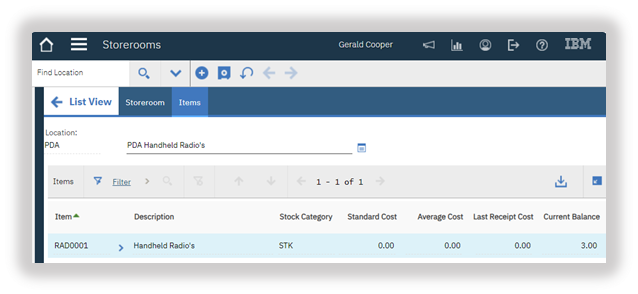

- Storerooms

Radio Assets are entered into Maximo as Rotating Items to help track the move history when Radios are issued, returned for repairs, and re-distributed when the Radios return from the Radio Manufacture. To have a Rotating Asset a Storeroom was required and the follow Storeroom was created in the Maximo

Storeroom Application:

Items:

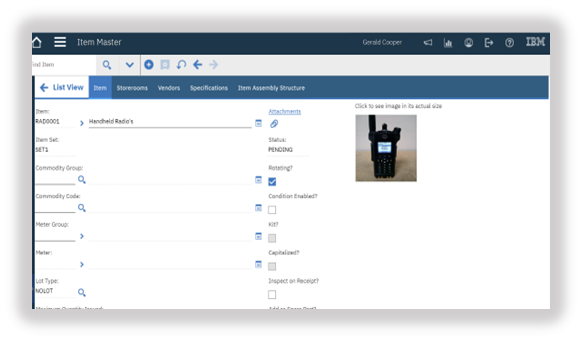

Item Master

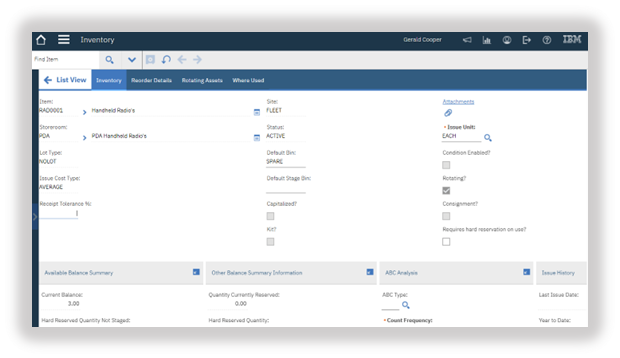

- Inventory

The Inventory Application for the Radio Project will be used to manage the Rotating Assets by the Inventory Manager. This is where the Rotating Asset will be identified and managed.

Inventory

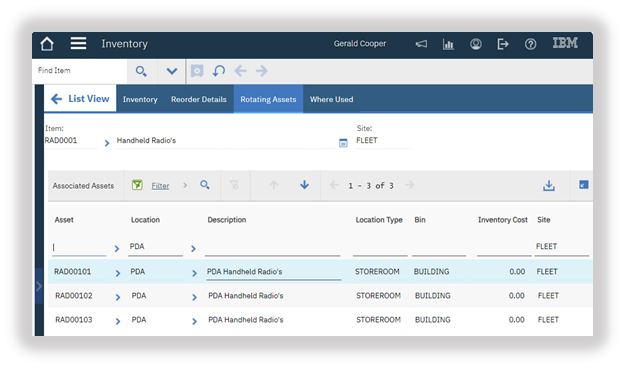

Rotating Assets

- Inventory Usage

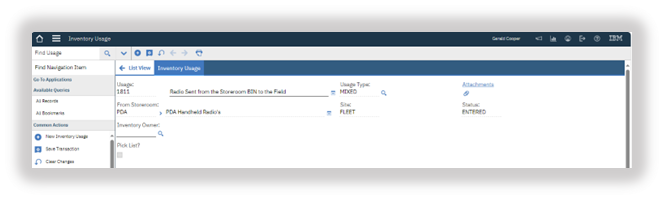

The Inventory Usage Application is used to move radios from the storeroom out to the field or OPERATING locations. This function is completed by the Inventory Managers, they will log into the Inventory Usage Application and create a new record filling in the values below:

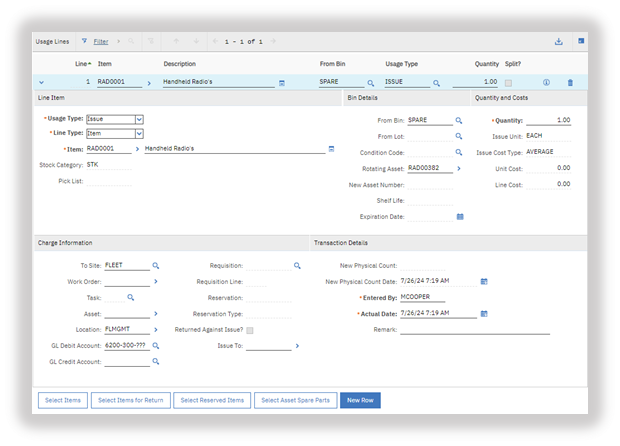

After they select new row and fill in the description and storeroom, they will go to the Usage Lines section and select “New Row”. The manage will fill in the Item, the Rotating Asset, and the Location where the department is located, and the Radio will reside.

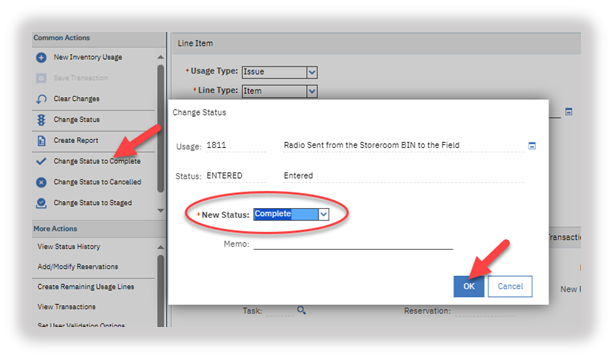

After all the Usage Line values are completed, the manager will navigate to the Common Actions Section and select the “Change Status to Complete” option and click OK.

This will complete the Radio Move from the Storeroom to the Department and OPERATING Location. At this point the radio will be distributed to the Department Supervisor, or the Assigned person, and the Storeroom Issue is complete.

- Start Center Templates and Security Groups:

- Department Supervisors:

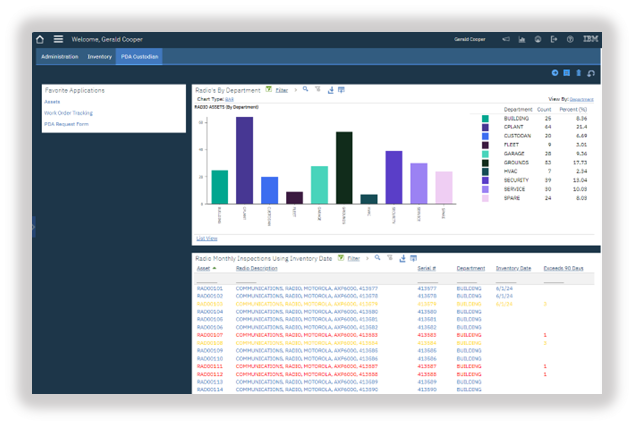

Department Supervisors are the persons who will make sure all radios are accounted for on a monthly basis Monthly. To do that they will have their own Security Group called “PDACUST” with an associated “PDA Custodian” Start Center.

Each month (or as needed) they will log into Maximo, and from the “Radio Monthly Inspections” portlet - filter by their department and when a Yellow or Red Asset highlighted record appears and indicates the need to account that the radio is in use and working as expected. Once they confirm the radio is with the Assigned To person, they will open the Radio Asset and change the “Inventory Date” to the current date, which will change the text to black text. (Note – configurations made to only allow the Dept. Leads to change the Assets “Inventory Date” and no other fields on the Asset.)

- Inventory Manages:

Inventory Manages are responsible for when the PDA Request is made to process the request and distribute SPARE Radios from the PDA Storeroom to the “Assigned To” or “Shared” Radios. They will process the request by approving the SR and then Issuing the Radio using the Actuals & Materials tab on generated Work Order.

- BIRT Reporting

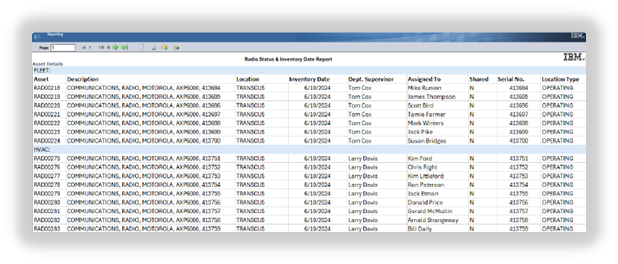

For this customer we developed two Radio Reports, one to list all Radio by Departments & Assignments and one report to be sent each month to the Department Supervisors that show the Inventory Date and radios that need inventoried.

- Report #1 – Radio’s Department & Assignments Report (Run on demand)

- Report #2 – Radio Status & Inventory Date Report (Scheduled to be sent to Dept Supervisors monthly)

BIRT Report Example:

Conclusion:

The following steps were used to develop this solution in Maximo:

- Documenting roles & responsibilities

- Gathering requirements

- Designing the solution

- Documenting the process diagrams

- Creating the functional and technical design documents

- Sign-off from the business stakeholders

- Building the solution in a Development Environment

- Conducting SIT and UAT and getting the business stakeholder signoffs of final design

- Creation of migration packages to PROD Environment

- Scheduling an outage and deploying the final migration packages to PROD

- Training to the Inventory Managers and Department Supervisors

This complete development cycle took approximately 4 months, the total time depends on the size of the organization and the stakeholder availability. Our satisfied customer was very happy with the results and this radio process is live and in use today.

Hope you have enjoyed this article, if you have any questions please contact Interloc Solutions. We would be happy to assist you with your Radio Management Processes using IBM Maximo.

About Mike Cooper

Mike Cooper is a Sr. Maximo Consultant for Interloc Solutions. Mike has been implementing Maximo for the last 24 years. He has performed in the roles of business analyst, project manager and solution architect. He has significant experience at all levels of business transformation and EAM implementation projects. He enjoys the challenge of solving both business and system problems. His greatest professional satisfaction comes from working with a team and getting the job done right. Mike lives in Indiana and enjoys outdoors activities with family and friends. He also enjoys sports and follows a handful of teams.